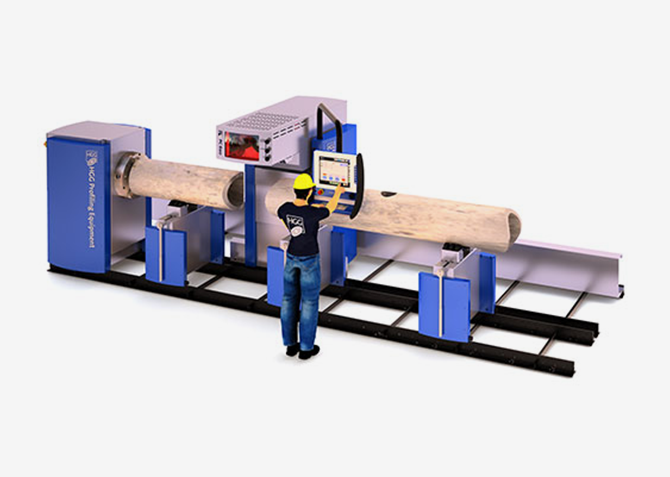

ProCutter 600–900

CNC Pipe Cutter

The PC 600 and PC 900 CNC Pipe Cutter incorporate all of HGG’s advanced technology and expertise. Operational excellence is applied to keep costs low. Both PC 600 and PC900 comes with oxy-fuel, plasma, marking and CAD-CAM Interfaces.

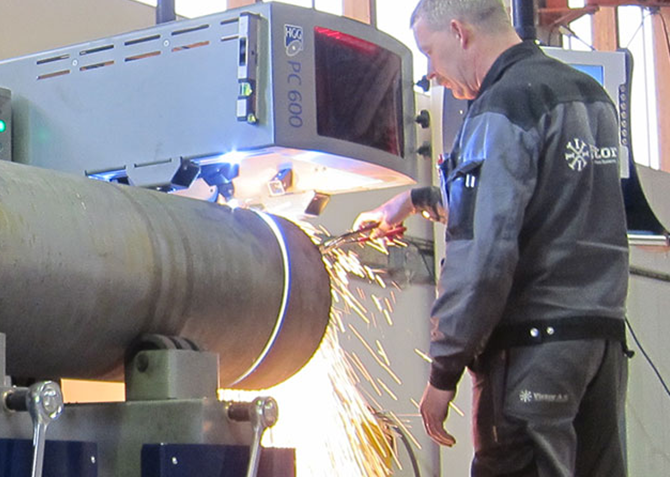

Partial Joint Penetration Welds

Equipped with both oxy fuel and plasma, the ProCutter 600–900 covers a wide variety of materials, sizes and wall thicknesses. Unique profiling shapes allow constant and efficient weld preparation despite the existing plasma limitation for tilting. The intelligent profiling shapes will automatically switch from a groove weld preparation to a fillet weld preparation (no extreme beveling needed) once the beveling limitation is exceeded.

Savings on Fitting & Welding

Too many welders are spending their time on laying-out cuts, manual cutting and grinding. Skilled welders are hard to find, a potential bottleneck in your fabrication process. Automate the pipe cutting process, allowing welders to do what they are best at, welding.

My first profiler

How many pipes need to be processed before you justify your investment in a plasma pipe cutting machine? The ProCutter uses HGG advanced technology, while keeping material and engineering costs low. The ProCutter 600–900 accomplishes this by keeping some machine operations less automated, while maintaining material size and maximum weight within a smaller pipe range.

CNC Pipe Cutter Applications

- Steel Construction

- Process

- Offshore

- Shipbuilding