RBPC 660–2000

CNC Pipe Cutting Line; roller bed type

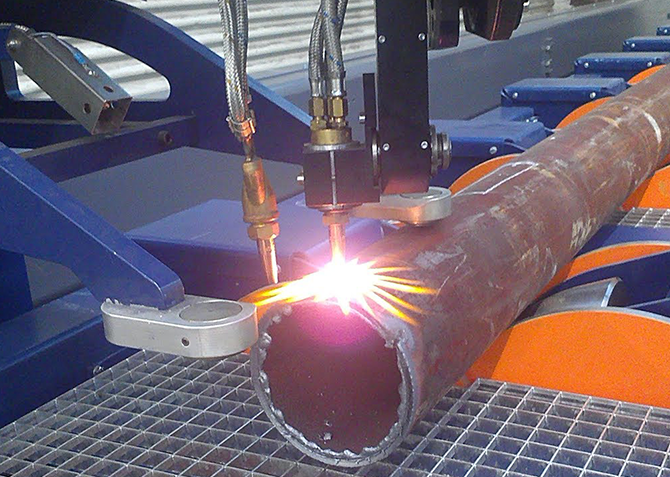

The RBPC 660–2000 is a highly productive CNC Pipe Cutting Line driven by a rollerbed. It comes with wheels sets and torch-to-material distance sensors dealing with pipe behavior during rotation.

Uninterrupted material flow

After loading material on the infeed buffer table, individual material lengths are fed into the cutting area with finished parts being fed out to the outfeed buffer tables for further processing.

PerfectFit™

It’s difficult to perform oxy-fuel pipe cutting on pipes which tend to be oval, often with weld seams. The RBPC uses tandem wheels to absorb a major part of these irregularities, resulting into a perfect fit, which in-turn strongly reduces fitting and welding costs.

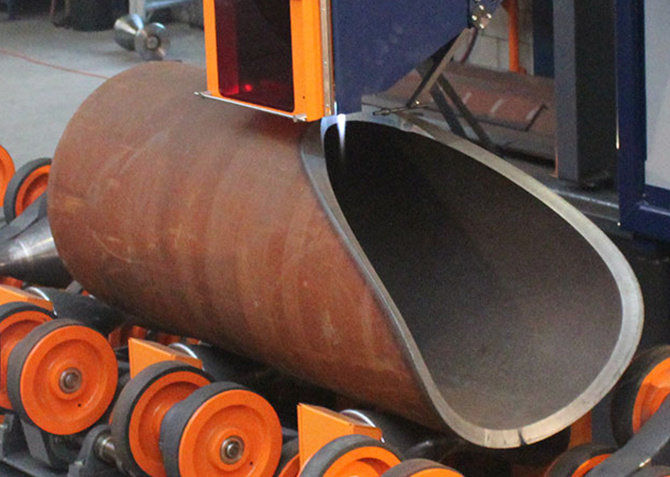

Perfect cutting shapes

Unique software routines allow compensation of the linear movement of a pipe being rotated. This results in an accurately matching lead-in and lead-out point of the cut.

Oxy-fuel Pipe Cutting Applications

- Process Piping

- Offshore Construction