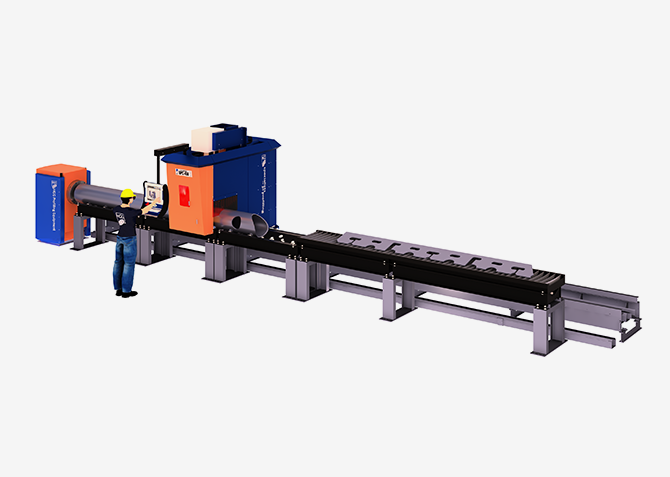

Ship Profiler

Profile Cutting Machine

Ship Profiler offers automated profile cutting for an affordable price, combining high productivity with a small footprint! Laser measurement is used to compensate material deviations and maximize accuracy.

Operator safety

The windowed cutting cell that closes the cutting process off from the operator and provides a barrier against noise, fumes and sparks. A two point fume and spark extraction system directly removes harmful substances away into a ventilation system.

Precision cuts

The patented biaxial cutting head with freedom of movement in tilt and rotation can precisely cut straight through and create bevels up to a 45° angle. HGG uses the minimum amount of axes with precise electric motors to cut accurately every time.

Accurate cutting

A 3D laser measurement system is attached to the torch holder. The 3D laser scan quickly calculates material inconsistencies, compares the theoretical model with the material and provides information for the cutting trolley to position the plasma torch accurately.

Automated Profile Cutting Applications

- Ship Repair Yards

- Ship Building

- Naval Ships

- Cargo Ships