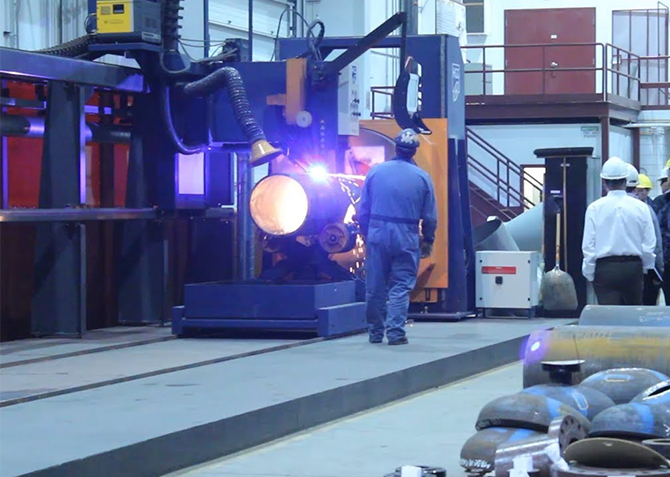

SPC 1500–3000 PT

CNC Pipe Cutting machine for vessels and offshore

The SPC 1500–3000 PT machine is a very robust machine built to handle large pipe diameters and heavy weights. Everything in the machine is designed with the purpose to guarantee extreme tolerances during cutting.

Savings on Fitting and Welding

Using skilled welders for laying-out cuts, manual cutting, grinding and is time wasted. These welders are hard to find and a potential bottleneck in your fabrication process. The SPC range automates these processes, allowing welders to do what they do best, welding.

Elimination of Lay-out

The amount of time spent on laying-out all cut-outs is very time consuming and often unsafe. After initializing on the zero reference point of the structure, accurate and fast positioning of the SPC marking/cutting tool allows for smooth operator control.

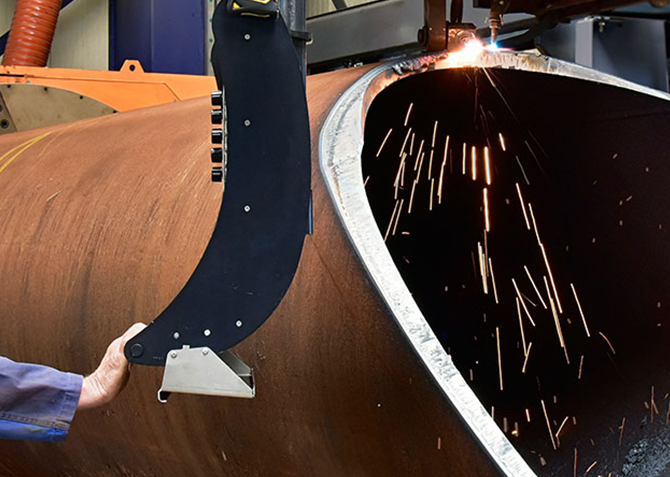

Thick Wall Accuracy

Deviations during cutting impact welding volume, especially on thick-walled pipes. This hampers your production throughput and increases your fitting and welding costs. The SPC 3000’s patented auto focus robot is designed for executing accurate positioning and movement.

Oxy fuel pipe cutting applications

- Offshore Fabrication

- Pressure Vessels